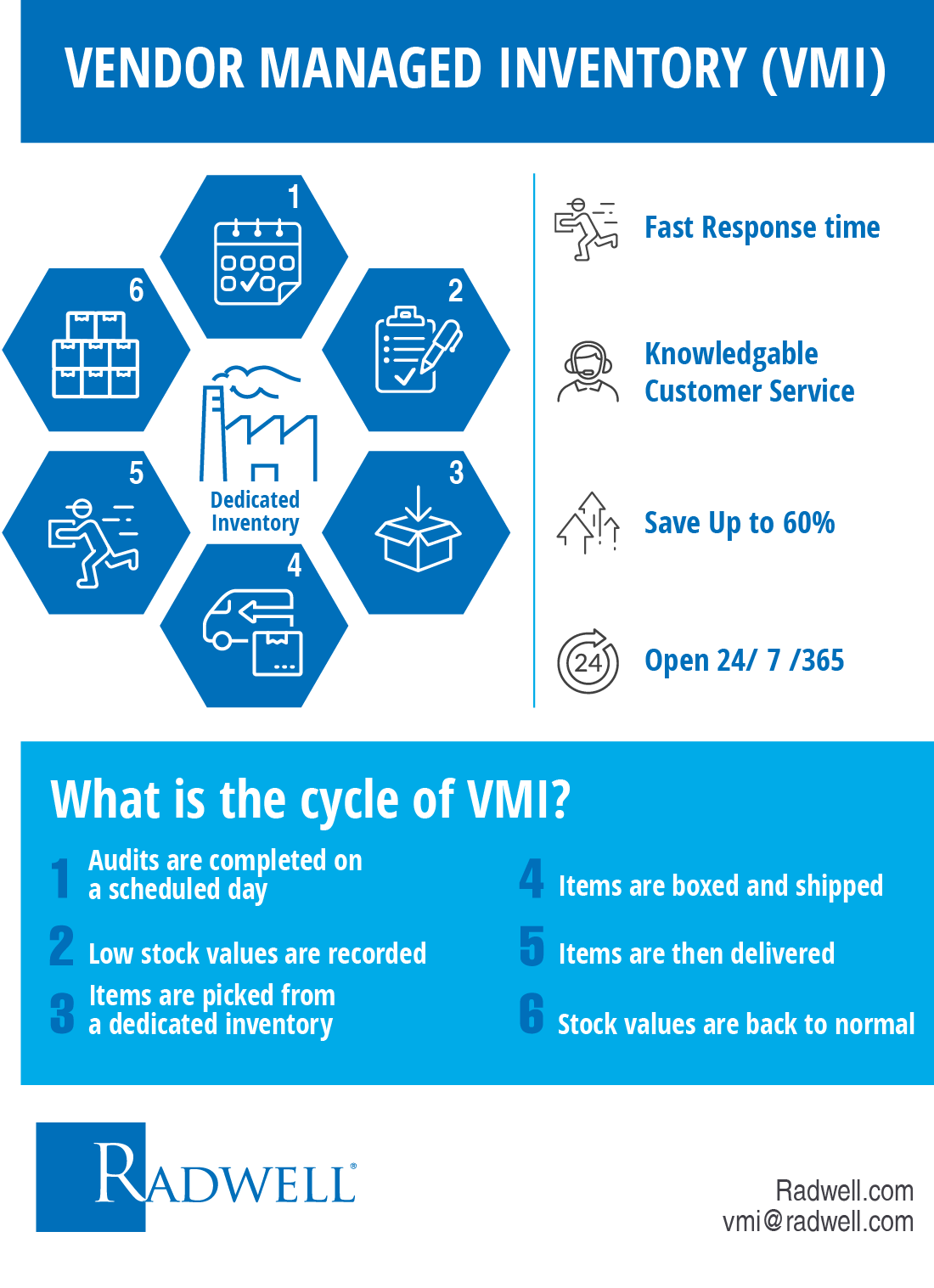

Did you know that Radwell’s offerings include quality supply chain solutions? We know that you’ll be more than satisfied with our VMI program because of the time and money saved. Plus we also have a great Customer Service Department to help when you have any questions.